Marketing of saddle pads has become big business. All one has to do is make a web search and you will find over 15 pages of manufacturers. Each pad company puts various marketing emphasis on their products. Emphasis ranges from comfort, fit, durability, ease of cleaning, cooling, compression protection, performance, close contact, blood flow to animal’s back and the list goes on.

Pad manufacturers “bias” their marketing labels to sell pads—bottom line! For instance, one manufacturer uses the term “wool like” on their label; another very expensive blanket/pad combination has the symbol used by the American Wool Council on the wear leather and yet close examination of the item shows it has a synthetic backed fleece, open cell foamed backed inner core and wool blend weave on top; another uses technical flattery – …two layers of air cells and ultra shock foam core producing lock down effect that eliminates slippage… Therapeutic is another big leader such as open cell medical memory foam, medical felt and … increase oxygen, energy, and muscle recovery. And all of the claims of being 100% wool only cloud the marketing hype.

Another glaring example of manufacturers of foam pads contradicting themselves is when they were interviewed for an article for Equestrian Retailer, July 2004, Vol. 7, No. 2. They give their bias on the benefits of neoprene products and then later state, “Manufacturers advise riders and trainers not to leave neoprene pads on horses for long periods of time because they build heat and moisture.” And this makes no difference whether the pad is perforated or waffled. It is impossible to channel air as they like to make one believe.

You can see that with catchy terms a saddle pad purchaser can easily be misled when trying to find the best compression protection, wicking and durability possible for their horse. Hopefully we can help you to understand some of the physical properties of pad materials simply by looking and feeling the pads surface and knowing where to find correct information.

SADDLE FIT

Before addressing the aspects of saddle pad materials one cannot over emphasize the importance of good saddle fit. If the saddle does not fit correctly soring will take place. Additional padding is only a temporary fix and will not solve the problem. In most instances if you are having problems with a pad staying in place you have to take a hard look at how the tree in your saddle fits the conformation of your horse. Because of expense, it is not practical to be changing saddles all the time so it is then necessary to find correct pad material that will stay in place, provide maximized compression protection and cooling.

SADDLE PAD HISTORY

Historically, saddle pads ranged from animal hides, to woven animal hair, to crude felts, to exotic linens, to woven blankets and today’s modern industrial materials. Old timers remember the hair, felts and blankets. Not much thought was given to saddle fit and if a horse became sore many riders added another layer and cinched a little tighter. It is important to remember that when ranchers used horses on a regular basis the horses were changed often, so soring was never a major concern.

It appears that the 1960’s began the era of synthetics. Dr. Robert Miller, DVM and noted author commented that early in his California practice in the 60’s, some of his clients started complaining about white spots and wither soring which had not occurred previously. Then one day he happened to spot an advertisement in a magazine for foam pads. Further investigation revealed his clients had switched to the new pads. Most of the early foams were closed cell mattress or seating type materials never intended for compression protection with severe impact.

It has not been until the last 20 years and the desire for perfection in saddle fit to enhance performance, that much thought was given to saddle pads. But as popularity of recreational riding and showing gained momentum more effort was put into the study of saddle fit and related accessories. Dr. Joyce Harman, DVM, an equine specialist, has spent the last fifteen years studying saddle fit. Dr. Harman wanted to know how saddle fit affected performance and what constituted good fit. However, as she studied saddle fit she realized the need to also assess what impact pad material had on saddle fit results. Her new book discusses findings with English style saddle fit and what to look for with pad materials. At some future date her findings on Western saddles will be available.

MATERIALS

The primary materials used in saddle pads today are open and closed cell foams, synthetic felts, needled felts, pressed industrial felts, woven blankets, gel packs, synthetic cloth, and air bladders. What is interesting about all of these materials is NOT ONE of them was ever originally designed to be used as a saddle pad.

Foams are petroleum and rubber based materials designed for sound proofing and impact resistance for automotive and aerospace industry. Felts were used for bedding, bearing cushions, lubrication wicks, sound proofing and cushioning in the same industries. Gel packs and air-bladder materials were designed for severe impact blows and mild weight distributions for auto racing, mattress industry and football helmets. Within the last 15 years another material, known as Tacky Tack was developed as shelving material for the food industry. Memory foam is another product that has just recently cropped up and is nothing more than a tight-grained open cell foam with low compression rating used in the mattress industry where impact applications are limited.

Now one would think that these would provide exactly what would be needed for saddle pad materials. Maybe and maybe not, but first a more detailed description of each.

Foam pads consist of two types of materials: 1. Closed cell – cellular rubber [neoprene] and 2. Open cell – polyurethane. There is also a closed cell, cross-linked polyethylene foam, but it is seldom used in pads.

Close inspection will reveal that the closed cell foam has a very tight fine grain. Whereas, the open cell foam has small holes and a grainy look generally. The closed cell foam normally has a more elastic and smoother feel. There are of course exceptions to these descriptions, but we are generally referring to what is used in saddle pad construction.

Color is normally black, white or gray.

With either of these foams it really does not matter if you know the difference because the compression ratings are about the same. Neither has wicking ability and both trap heat. If it is open cell foam used as filler just remember that compression protection is extremely poor. Closed cell foams tend to send pressure points through to the horse’s back, but can be supportive if under a heavy saddle. Open cell foams will bottom out but do not interfere with saddle fit by being too thick.

Gel Pak Pads are simply heavy mill vinyl/plastic bladders that are filled with a non-hardening gel material. The intent behind development of this product system was to find a material base that would lessen severe impact from a sharp force. In other words it would gradually give with the impact. Evaluation of this material when used in saddle pads works fine when used for only a short time period (30 minutes). But with any movement after that period of time they will bottom out. This leaves no compression protection below any pressure points that might exist in a saddle. This happens because the gel is pushed aside.

The other major down-side to pads with gel paks is the plastic bladder as it traps heat and has zero wicking ability. These Gel Paks are normally bonded between other synthetic products. And even if they were bonded with a better grade of felt no real benefit is gained because compression protection is no better than the felt by itself and it adds unnecessary weight.

Air bladders or air cell pad material simply are different forms of creating an air mattress. They will conform to conformation of animal and saddle bars, but they are harder to keep in place because of constant ripple effect, like in an air mattress or waterbed. They will work with limited riding (30-45 minutes) but for a hard days work they trap heat. Air can have very limited compression protection because of the bottoming out effect similar to Gel Pak pads. Air also becomes quite hard under the pressure of the saddle, and though it gives an even surface the pressures are higher than most other materials. Most of these types of pads have to be bonded with some other synthetic material and those that are not are very tacky when sweaty. Manufacturers try and convince you that airflow keeps them cool under the saddle. Again this is not possible with a saddle that fits correctly.

In the felting world there are two types of felt: 1. Needled felt and 2. Pressed industrial felt. Generally most synthetic felts are needled. “Needled” simply means it is made with heat, stem and vibrating pressure from needles that lock the fibers over the top of each other. “Pressed industrial” felt is made by heat, steam and oscillating pressure that locks the wool fibers together by sticking fibers to each other. In this case fibers are able to lock to each other because of the outer surface structure of each individual fiber. It requires a separate technical article to show why this process works.

Needled felts are easy to spot. They have horizontal and vertical holes evenly spaced on both sides of the felt. Because of high concentrations of synthetic material in them they are generally shiny, slippery and not soft feeling. Their color ranges varies from black, to dark grays, to motile grays with lots of color thread showing, to white, such as medical hospital felt. Most neoprene pads with colored felt on them are 100% synthetic or needled felt with high concentrations of synthetic material and a cloth cover. Another clue is that when you see felt pads sewn around the edges or another material sewn on top, you can bet it is a synthetic or needled felt, because they will not hold together with much use without this sewing effort.

Manufacturing costs of these pads are substantially less due to cheaper costs in synthetic materials. But from the retail point of view when you compare the cost of synthetic pads there is not much price difference.

Pressed industrial felts (PIF) do not have the holes. They are softer to touch, much more supple and depending on grade have no shiny synthetic material. Color ranges are dark gray to off white in the natural state, but with the better grades of PIF one can find all other dyed color spectrums. Color normally gives you clues as to the actual virgin wool content and grade of felt. The more virgin wool in the felt, the lighter the color is. The same is true for touch. The more virgin wool content, the softer the feel will be when touching.

There are about 15 grade specification numbers utilized by the felting industry. Most saddle pad makers use an F15 grade. This F15 felt has a dark gray, almost a charcoal look. It contains 55% maximum virgin wool and 45% reworked wool content. This felt is used solely as a pad and/or bonded with one of the foams.

(Note: Reworked wool comes from yarn previously processed for some other application, normally in the garment industry, and has been blended with synthetics. Felters use it to control density, consistency in thickness and cost. The synthetics can then end up being as high as 20% in any given pad. So color is only clue a buyer has to tell whether or not the felt is really 100% wool as labeled. )

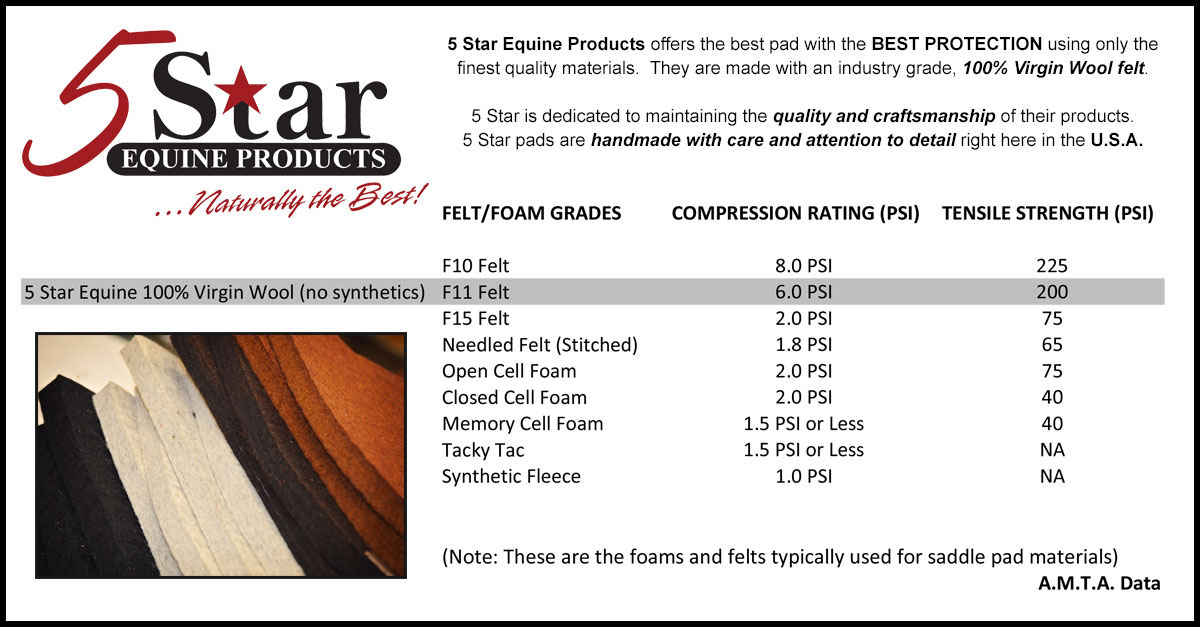

(EXCEPTION) There is a company that uses F11 and F10 grade wool felt. The F11 felt has 92% minimum virgin wool and 8% reworked content. The F11 is very light gray, very soft, smooth finish and very supple. The F10 felt which has 98% virgin wool content, and 2% reworked wool. The F10 is a crème white and very soft with a smooth finish. These felts are dyed with a vegetable based dye to come in a variety of colors red, blue, hunter green, brown, black, etc. The exceptional features of these felts make it very easy to visually tell them apart.

So what difference does it make when someone wants a wool felt pad and why would they look for a F10 or F11 felt as opposed to a F15 felt. International Felting Standards shows that the F11 felt has a compression rating of 6 psi and 200 psi tensile strength as opposed to compression rating of 2 psi and 75 psi tensile strength for the F15. Additionally, based on research from Felt Manufacturers Council of America, the higher the virgin wool content of the felt, the better the wicking ability is. So if you really want a pad with superior rating find the company with the F11 and F10 felt.

WHAT TO LOOK FOR IN A PAD!

The most important of all the pad attributes to look for is compression protection and cooling. How does the purchaser know whether the manufacturers label and claims are true? Answer: They don’t without careful investigation and lots of costly trial and error in purchasing pads.

COOLING

When we look at all the research done over the years with exercise physiology and anatomy for humans and equine we know that the mechanism for cooling during activity are sweating and breathing. To prevent over heating during exertion the body must receive airflow or some means of water internally or externally for cooling to take place.

So let us apply this knowledge to saddle fit and cooling.

When a saddle is fitting correctly, the bars of the saddle tree should conform evenly to the natural conformation of the back. And there should be a flair or rocker at the front and back of the bars to allow the shoulders and loins freedom from pressure. The saddle maker then adds leather skirting to the top and a wool sheepskin or synthetic fleece material to the bottom. Very few saddles today have natural sheepskin on the underside unless it is specifically requested. Assuming this material has been fitted and placed correctly the saddle should conform to the horse’s back for a nice fit. The logical question to ask then is how can cooling take place under a saddle if it fits closely to the back?

Answer: It cannot without the support of material that will wick the sweat, which is the primary heat-carrying agent.

Common Sense Time

Closed cell foams and synthetic based materials will not wick. Try mopping up five gallons of water with a neoprene or synthetic pad. So a good question to ask oneself is, “If my saddle is fitting correctly and no air flow or water can penetrate between back and saddle, how can I cool the saddle back area with a neoprene or synthetic pad?” Answer: Not Possible! Another good question to ask is “Would I wear plastic or foam underwear or socks?” Answer: Not on your life! The argument that a sweaty back lubricates and is good for the animal is shear ignorance.

There are quite a number of manufacturers that contend their air-channels and waffle type foams cool. This is simply not true because the animal hair, skin and fat layers push into holes in the material. This can easily be seen through close examination of the back after using one of these types of pads. Again, always remember the tight fit saddle concept.

Other points to consider are that when any foam-based pad becomes wet from sweat they also become sticky or slick. When this happens the animal hair and skin is constantly being pulled or stretched creating the frictional heat which can create gall points and sores.

The only true method of cooling is by using a pad material that will wick. In today’s equine market the only two materials are wool or cotton. Wool is the winner here. It will absorb up to 3 times its weight in water, cotton will only absorb its initial weight, and wool has compression protection six times that of comparable thickness of cotton.

No official data really exists on the attributes of various materials on its abilities to cool.

Recently we took a trip to the Hell Roaring Wilderness area in Montana. As a part of the trip we wanted to obtain actual data about cooling with various types of pad materials. We purposely used a saddle that was extremely much too narrow in the front, knowing it would pinch and rock on the huge, flat backed draft, Quarter Horse cross horses and mules.

The trip into camp was 21 miles. Once at camp we did numerous day rides that amounted to 3-6 hours at a stretch.

In order to secure a range of data we took rest temperatures of each animal before starting each ride, while riding, cinched at rest (lunch break and fishing – one hour) after exertion and at end of day just before unsaddling.

Trip Data:

Digital read out temperatures were taken at the tightest point of the shoulder and saddle. At rest the readings consistently ranged from 98.5-99 degrees. During exertion the felt pads stayed consistently at these same temperatures, but the F15 felt generally ran a degree higher than the F11. During exertion the neoprene, neoprene-felt pads, synthetic fleece and Tacky Tac used with a blanket were always 3 degrees hotter, and after one hour during lunch breaks these pads never cooled down. Finally, at the end of a day ride the temperatures initially established had not changed.

The pads represented materials from some of the major known manufactures that the outfitter had been experimenting with in an attempt to find pad material that would cool to prevent galling, have superior compression protection and longevity. Some of the pads he had been trying were Cowboy Choice-Closed Cell Foam/Felt, Wrangler 20x- Closed Cell Foam/Synthetic Top, Justin-Closed Cell Foam, Equibrand-Closed Cell Foam/Felt Top, Reinsman- Tacky Tac Bottom, Synthetic Top, Toklok-Needled Felt, Slone-F15, 5 Star- F11, Tacky Tac – Tacky Tac w/ Blanket Cover, and Coolback-Synthetic Fleece. This seems like a lot of brands, but one has to realize that on any given trip as many as 45 head of mules and horses can be saddled or packed. Plus this outfitter had been searching for years to find a pad that would assist in compression protection and cooling.

The findings were exactly as we suspected. Open and closed cell foams, layered felt foams; synthetic felts and fleeces did NOT cool and trapped heat. Temperatures were significantly higher. The felt pads were the only materials that kept consistently lower temperatures. In one case with one of the solid neoprene pads one horse’s back was so tender after use that it could not be used for two days.

The data speaks for itself and we only mention the name brands because out of these, Slone and 5 Star were his only wool felts. The rest of the pads were all neoprene or neoprene/felt combination pads (synthetic or F15 felt tops) and synthetic fleece.

COMPRESSION PROTECTION

Compression protection with pad materials is easily measurable and is a direct function of tensile strength and rebound resistance in terms of pounds per square inch. The chart below represents data taken directly from the American Materials and Testing Institute, International Felting Standards, Automobile Testing Institute and material manufacturers.

Data:

Felt /Foam Grades Compression Rating (PSI) Tensile Strength (PSI)

(Note: These are the foams and felts typically used for saddle pad materials.)

Gel Paks and Air Bladders measurements at “bottom out points” are generally 1.5-2.00 or less and because of the material flexibility it is hard to get accurate ratings. Tensile strength is not an issue because it is normally bonded or sandwiched with some other material(s).

Conclusion:

Good ole common sense really needs to prevail with saddle padding. Remember – First if the “shoe don’t fit, the shoe still won’t fit with lots of socks.” If the saddle doesn’t fit, no padding in the world will solve the problem. In fact additional padding can in many cases shift the problem elsewhere or create additional cinching and soring. It also must be pointed out that with a good custom saddle, thinner padding can be the answer.

Over the long haul with or without good saddle fit, high quality wool felt materials are the best bet. If your intent is to only ride for 30-45 minutes and activity will be minimal; likely no harm will be done using foam, tacky or neoprene material, but can be very uncomfortable to the animal.

Bottom line is if you spend $5000 for a horse, $3000 for saddle and $60 for a pad something is not computing. If you wouldn’t wear the material on a hot or cold day WHY in the world do you think it would be good for them?

Points to Ponder:

- If the saddles don’t fit they can push pads out the back.

- A saddle tree may be warped if it pushes pad out the back and to the side.

- If you wouldn’t wear that stuff for underpants or socks why put it on the animal!

- Synthetic pads have the highest profit margin for makers.

- Sweat pouring off a back is like you standing on ice with tennis shoes on a hill!

- Do you like having bandages pulled off your hairy arms? So how do you think tacky material feels to an animal?

- Wool felt pads are easily cleaned!

- Synthetic fleeced saddle skirting is slick and will present problems with most pads.

- Don’t be fooled by Patent Pending in advertising.

- Synthetic foams are not UV light resistant and break down,

- Synthetic foams break down from heat and salts of the animal.

- Fire or strong acids are the only thing that will harm wool.

- All pads will contract and spread disease when not cleaned if infection exists.

- Pinch pads with thumb and fingers. If you can feel the other digit it likely has bad compression protection.

- Buy for function first, then looks.

- Don’t be fooled by gimmick terms and pictures.

- Ask construction specifications of retailer and manufacturer.

Shop 5 Star’s full line of 100% pure wool, fully customizable pads today!